New technologies have made membrane switches increasingly complex.

And that’s a good thing, as these switches perform complex tasks, whether it’s for electronics, medical devices or military applications.

Manufacturing membrane switches requires both technology and expertise. We’re proud to offer both, and we’re always happy to take questions from customers about how membrane switches come together. Here are some of the most common questions we get about membrane switch production.

How long does it take to produce a membrane switch?

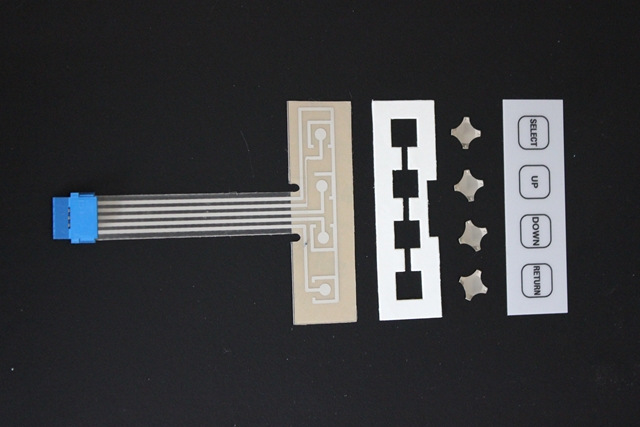

There are typically a few components involved in fabricating a switch:

Artwork

The first step is making sure the art is correct, a process that typically takes between one and three days, depending on the complexity.

Printing

The next step is the actual printing process, the length of which depends on how the membrane switch is being printed.

For larger volume projects, if the switch is being screen printed, your manufacturer would need to make a film and create screens before the printing process begins. This typically takes two days.

If the membrane switch is printed with digital printing – as opposed to silkscreen printing – the process is more direct. Once the art files are approved it gets tucked out for printing on a larger sheet.

Volume is a major factor here as well. Printing just a few membrane switches will of course be a shorter process compared to printing a higher quantity.

Fabrication

Membrane switches can be done using virtually any material, but the two most common are Lexan and Mylar. Lexan is a polycarbonate material prized for its durability and clarity.

Mylar is the trade name for a type of a polyester film created using polyethylene terephthalate and prized for its tensile strength and transparency.

When we make a membrane switch, we typically reverse print on Lexan – either 0.010 inches thick or 0.015 inches thick – allowing you to look through the Lexan to see the printed copy, meaning the ink is not exposed to the elements.

This way, the Lexan can sustain abrasions, chemical exposure and other damage, while the ink remains protected. People can touch the membrane, but the ink will not wear off.

Other common questions

- Can we make a switch with an 8-pin connector?

We can make a switch with anywhere from three to 12 pins, although the most common number.

- Can we insulate?

We have two methods for providing membrane switch insulation. The first option is to insulate with another layer of material, in this case mylar. This layer allows large or small portions to be insulated with custom cuts, or simply lets us insulate the entire layer.

The next option is to print a layer of insulating ink, called Dielectric. The printing method allows for specific areas to be targeted for insulation.

In addition to providing insulation between conductive layers, we can also insulate the tail, which comes out from behind a keypad and connects to a circuit and the rest of the equipment.

- How many buttons can we provide?

We don’t have a limit.

- Do you make prototypes?

We do. We pride ourselves in very short quantity runs.

Does your application require a custom membrane switch? Turn to Industrial Nameplate, where we can help you find the ideal blend of material and imaging technology to create custom membrane switches for everything from kitchen implements to defibrillators.

Contact us today to learn how we can use our 50-plus years of membrane switch experience to bring your design up to date.